Riveting Equipment Series

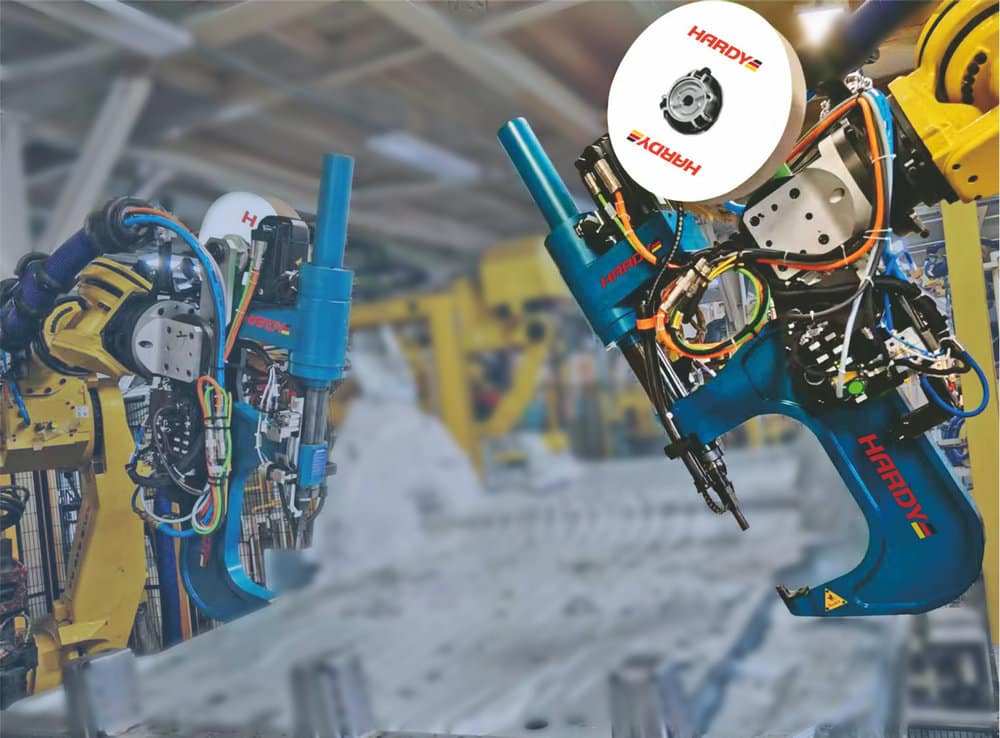

HDSPR Self-Pierce Riveting System

HDSPR Self-Pierce Riveting System

Self-piercing riveting is a process used to join two or more layers of material without pre-drilling or punching. Self-piercing rivets are the fastener for emission-free joining of aluminum parts, mixed joints, and combined joining and bonding.

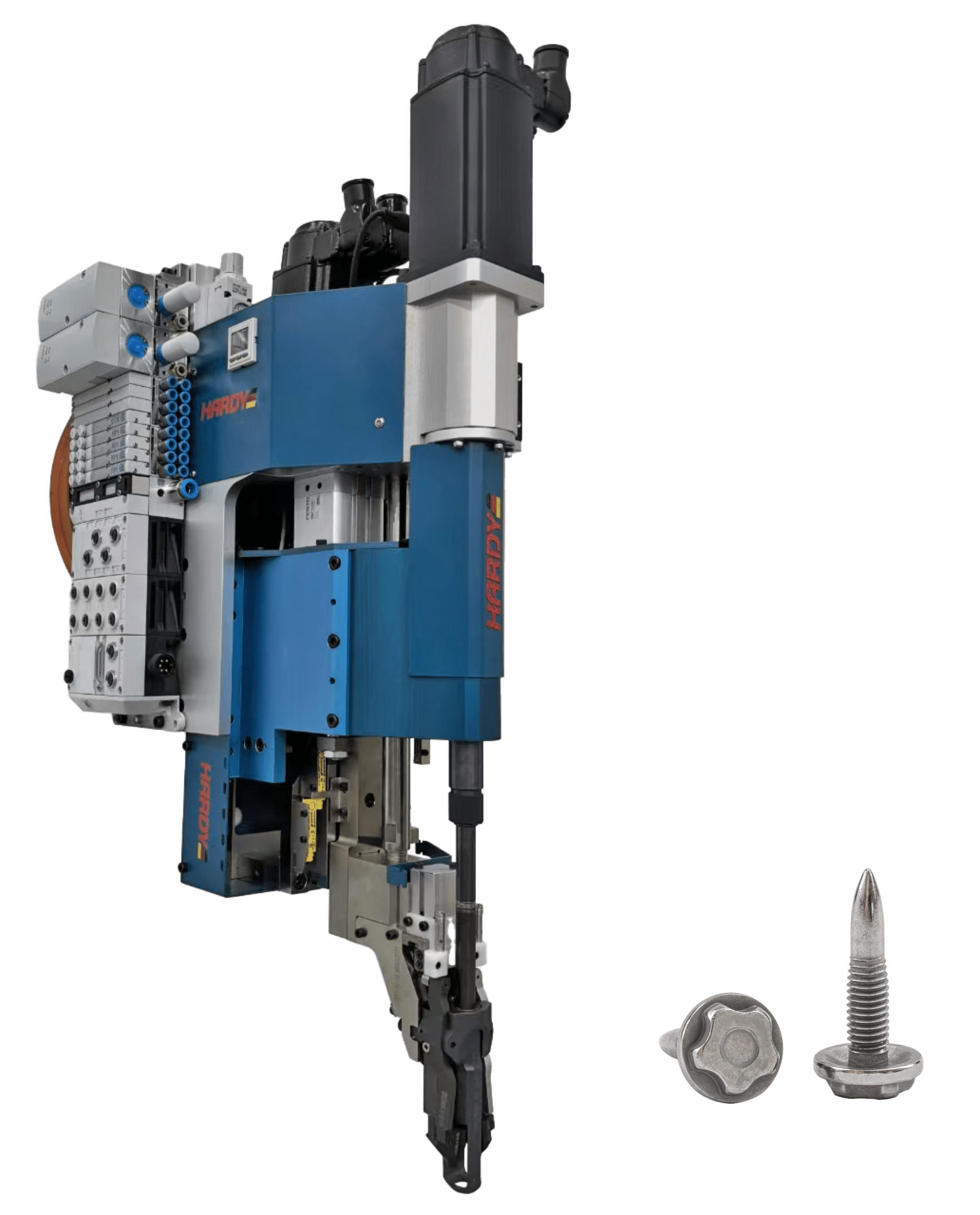

HDFDS HARDY Flow Drill Screw System

The HDFDS Flow Drill Screw System uses HDFDS hot-melt rivets that pierce the material, drill a hole, tap, and tighten under the combined effect of high-speed rotation of the equipment and axial pressure to achieve a fixed form. This technique is suitable for single-sided and closed-cell sheet metal connections. The riveted plates include steel+aluminum, steel+steel, aluminum+aluminum, and non-metallic material+metal connections. The rivet connection can meet the single-sided connection requirements of thick walls and closed-cell structures.

HARDY Clinching

Clinching is a forming technology for joining sheet metal, tube and/or profile parts made of steel, stainless steel, and non-ferrous metals (especially aluminum). The clinching technique enables two or more overlap-arranged joining partners to be connected exclusively on the basis of local cold forming.

Video Presentation

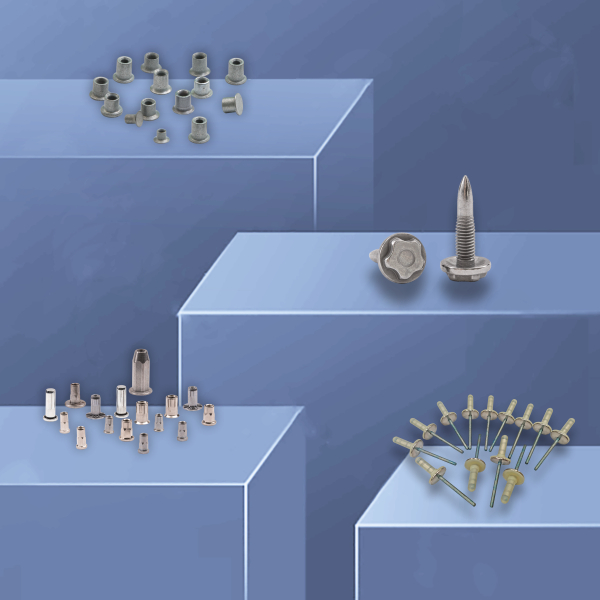

HDRNS HARDY Rivet Nut System

Patented floating head design enables X/Y.axis and angular adaptive riveting

Adaptive Sheet Metal RivetingDual servo drive system with full-processmonitoring

Up to 60kN setting force (M16 and belowcompatible)

Quick-change head configuration

HDFRS HARDY Press-Riveting System

Press-riveting is an efficient fastening technique used for joining metal sheets. It permanently fixes fasteners (such as press-rivet nuts, press-rivets etc.) onto the metal sheet through a cold extrusion process.

HDRMS/HD RCSHandheld Rivet setting monitor/control system with automatic fastener feeding

The unique feature of blind riveting is that it only requires access from one side of the workpiece, making it ideal for confined spaces. In contrast, screw fastening, hammer riveting, and press riveting require access to both sides.

A blind rivet consists of two parts: the rivet body and the mandrel. During setting, the tool’s pulling jaw draws the mandrel, expanding the rivet’s body into place. The mandrel then breaks at a pre-set breaking point and is acquired via a vacuum tube. The remaining mandrel stub provides high clamping force, offering excellent tensile and shear resistance.

Blind rivets are available in various designs, materials, forms, lengths, and colors. Depending on the application, users can choose from standard off-the-shelf rivets or custom-engineered rivets for specialized requirements.

HDHTF HARDY -Handheld Cordless Interlock riveting tool

Large stationary workpieces

Prototype production in R&Dworkshops

Supplemental connections onproduction lines

Field installation andmaintenance

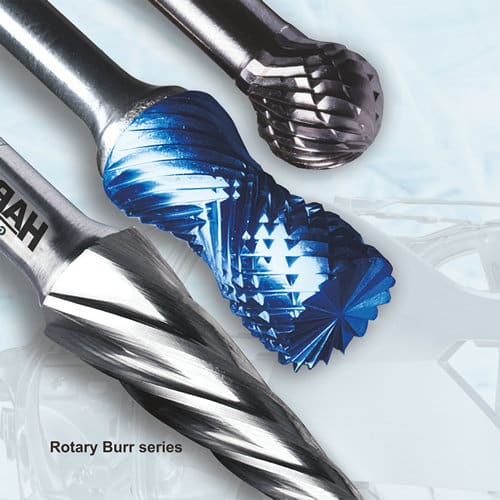

Other product categories

How to find us

Postal address: Auf der Koppel 7 | 58540 Meinerzhagen

| Title | Address | Description |

|---|---|---|

Hardy Industriewerkzeuge | Auf der Koppel 7, 58540 Meinerzhagen, Deutschland |

Phone: give us a call +49 2354 70683 00

| Title | Address | Description |

|---|---|---|

Hardy Industriewerkzeuge | Auf der Koppel 7, 58540 Meinerzhagen, Deutschland |